- Ms. Fisk

- 11 minutes ago

- 1 min read

All Posts

- Ms. Fisk

- 7 days ago

- 1 min read

Updated: 7 days ago

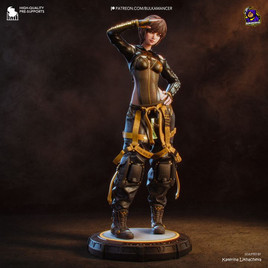

Here's the upcoming monthly releases announced by Bulkamancer Sculpts and h3LL Creator

Bulkamancer - March Releases

h3LL creator - March Releases

As always, with these new releases, these models will be added to the shop, starting March 1st.

- Cellphish Art

- Feb 24

- 1 min read

This week saw the grand opening of CuriosForge, our Etsy branch storefront that focuses on offering premium 3D printed items for TCGs, TTRPGs, Wargaming and collectibles that don't quite fit the main offerings of Curios of the Abyss.

Unlike this shop, CuriosForge focuses on limited runs and small batch production of items instead of Made to Order or mass production. Gaming supplies, miniatures, toys and one-off busts will be the main focus of the shop, so keep close and frequent eye on this shop as it grows, as it will rotate through the items it offers (but there will be consistent staples you can always find)